About

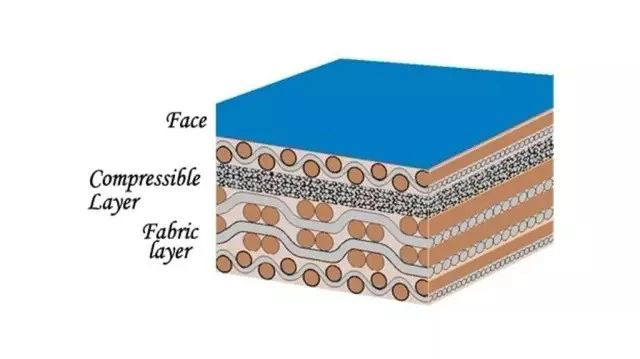

Offset printing is indirect printing. It is a printing method in which the graphic information on the printing plate is transferred to the blanket, and then the graphic information is transferred to the substrate through the pressure between the blanket and the impression cylinder. There is no doubt that the blanket is played an irreplaceable role in offset printing. Therefore, the quality and selection of the blanket has become an important part of offset printing quality control.

So how to choose a reliable blanket?

Uniform thickness

The uniform thickness will make the printing pressure evenly distributed, and the ink color will be more even when printed, and the size of the image and text is not easy to change during the process of image and text transfer.

Good flexibility

The higher the elasticity of the blanket, the stronger its instantaneous resilience, the more it can adapt to high-speed printing, the better the dot reducibility, and the more authentically reproduce the original.

Appropriate surface roughness

The surface roughness of the blanket will affect the printing characteristics such as paper release, solid density, dot change, and printing contrast. Controlling the surface roughness is very important to the printing quality.

Oil and solvent resistance of the surface rubber layer

During the printing process, the ink will penetrate into the surface rubber layer of the blanket. If the surface rubber layer has strong oil and solvent resistance, it will be easier to clean and the ghosting phenomenon will be weaker.

Strong recoverability

The rubber blanket used for a long time is permanently deformed due to compression fatigue, resulting in a change in the thickness of the blanket. If the rubber blanket has good recoverability, the thickness change will be less and the service life will be prolong.

Small elongation ratio

If the rubber blanket has a small elongation ratio, a compact structure and a high mechanical strength, which is beneficial to increase the tensile strength and reduce the deformation of the image and text transfer.

Good ink absorption performance

The blanket has good ink absorption, which can ensure that the ink color is even, the writing is clear, the printing dots are smooth and the dot expansion rate is small during the printing process.

Strong oxidation resistance

In the process of cleaning the blanket, car wash water etc. easily penetrate from the edge of the blanket, causing uneven edges of the blanket, especially when kerosene, gasoline, etc. are used to clean the blanket, the damage to the blanket is greater.

2021-07_24

Hang in there, light is coming soon Email: [email protected]

Tel: +86 185 6997 1958